Tungsten carbide Burr ranges through ANSI Standard and DIN Standard and has different carbide grades suitable for different purposes. If necessary, our engineer will recommend the proper tungsten carbide grade as per different use. We’d like to offer more specific technical data about our products.

Application for Tungsten Carbide Rotary Burr:B. Cobalt (Co): 6%

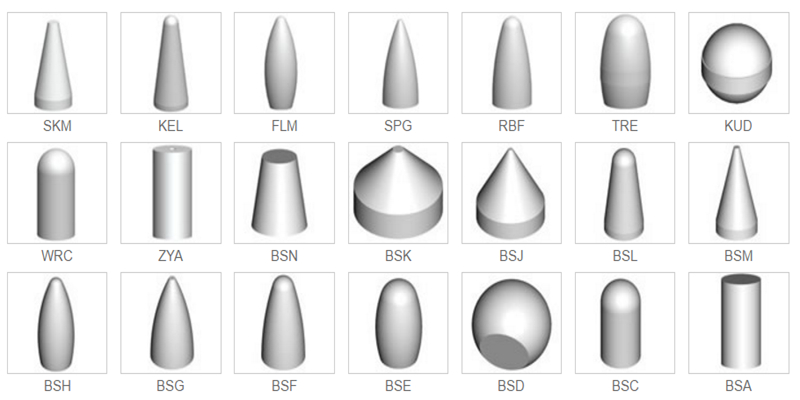

Tungsten Carbide Rotary Burr

2. Physical Properties:

A. Hardness: 90.0 – 92.5 HRA

B. Density: 14.40 – 15.00 g/cm3

C. Maximum Porosity:

1.Type A: 02

2.Type B: 02

3.Type C: 00

D. Transverse Rupture

Strength: 320,000 Ib/in2

E. Average WC Grain Size: 2.5 μm

3. Constant of Metallurgy

A. Free of ETA-phase

B. Uncontaminated by other carbide grades or contents

Contact: Sales Apt

Phone: 0577-62666977

Tel: 0577-62666977

Email: info@jing-xin.com

Add: No. 181, Jing 6 Road, Economic Development Zone, Yueqing City, Zhejiang Province